In woodworking, automotive, art, and metalworking fields, paper-based sandpaper is one of the most basic yet sophisticated tools. However, many users are often confused:Why does sandpaper come in so many colors?Is the color decorative, or does it have practical significance? Does it represent particle size? Does it indicate its purpose?

In fact, the color of sandpaper is not random, nor is it merely for "looks good," but rather determined by...Abrasive types, coating processes, backing materials, and brand differentiation systemsIt is determined by a variety of factors. Understanding the performance logic behind the color helps us to choose sandpaper scientifically, improving sanding efficiency and surface quality.

1. Where do the colors come from? It's not simply a matter of "dyeing".

- Abrasive original color:Different abrasives have their own colors. For example, alumina is brown/white, silicon carbide is black/green, and ceramics are purple/blue, etc.

- Dorsal staining:Paper/cloth backings are dyed to enhance recognizability, such as yellow, blue, or purple backings.

- Coating additives:Anti-clogging agents and cooling coatings can also affect color performance.

- Brand Identity System:Colors are sometimes used to distinguish different series, but the definitions vary from brand to brand.

II. Color ≠ Grit: A common misconception about sandpaper

Many people mistakenly believe that "the darker the color, the finer the sandpaper" or "yellow sandpaper is coarse and white sandpaper is fine," but these ideas are inaccurate.

Correct understanding:Color is approximately a combination of material, craftsmanship, and product category; it does not directly represent the fineness or coarseness of the material.

III. Common Color Sandpaper Comparison Table

| color | Abrasive type | Back base structure | Features | Typical uses |

|---|---|---|---|---|

| yellow | Alumina | Flexible paper base | Economical and practical, suitable for dry grinding | Carpentry, putty layer |

| Reddish-brown | Alumina | Paper/Cloth | Versatile and adaptable | Woodwork, primer |

| blue | Zirconia/Ceramics | Strengthen paper base | High machinability and heat resistance | Metal, hardwood |

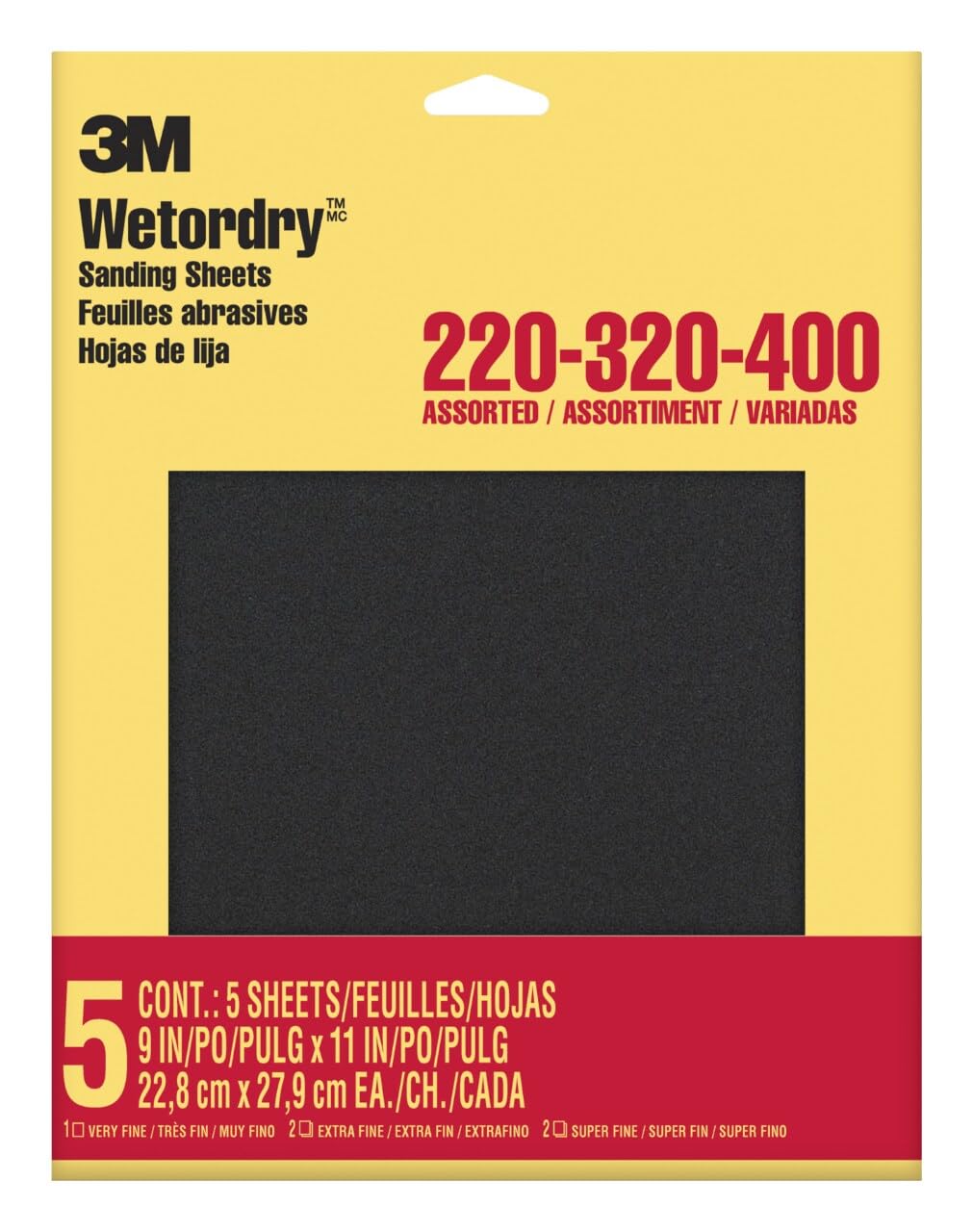

| black | silicon carbide | Paper base | Sharp, suitable for wet grinding | Paint, glass |

| green | Silicon carbide/ceramics | Industrial paper base | High hardness and good heat resistance | Glass, alloy |

| White | White corundum | Fine paper base | Fine and not prone to clogging | Clear coat |

| Purple | Ceramic + Coating | High-end composite paper | Anti-clogging and long lifespan | Industrial Grinding |

| grey | Synthetic abrasives | Soft paper base | Gentle and safe | Refinishing and polishing |

IV. Three Steps to Scientifically Selecting Sandpaper

- Confirm granularity (P-value)For example, P80 = coarse grinding, P240 = fine grinding.

- Judging abrasiveFor hard materials, choose silicon carbide or ceramics; for wood, choose alumina.

- wet grinding or dry grindingSilicon carbide is suitable for wet grinding, while alumina is mostly used for dry grinding.

V. Practical Sanding and Color Matching Suggestions

Carpentry process:

| stage | Recommended colors | illustrate |

|---|---|---|

| Initial grinding | Reddish-brown, blue, purple | P60–P80, fast material removal |

| medium grinding | Reddish-brown, yellow, blue | P100–P150, leveling |

| fine grinding | Yellow, white, gray | P180–P320, Surface Preparation |

Metalworking process:

| stage | Recommended colors | illustrate |

|---|---|---|

| coarse grinding | Black, blue, purple | P36–P80, cutting strength |

| medium grinding | Green, purple, reddish brown | P100–P150, transitional polishing |

| fine grinding | White, black, gray | P240–P600, Polishing Preparation |

6. Why do sandpaper brands like to use animal names?

The table below summarizes the animal names used by common sandpaper brands, their corresponding symbolic meanings, and the product characteristics behind them, for easy understanding and reference:

| Animal Name | Representative Brand | Symbolic meaning | Implicit product characteristics |

|---|---|---|---|

| Eagle | Eagle (China) | Sharp, precise, and with a wide field of vision | High cutting force and sharp grinding, suitable for precision machining. |

| Deer | Deerfos (South Korea) | Agile, docile, and adaptable | The sandpaper is soft and suitable for handmade woodwork and sanding curved surfaces. |

| Elephant | Elephant Brand (China/Taiwan) | Heavy, durable, and stable | The abrasive has high durability and is suitable for large-area rough grinding. |

| Lion | Lion Brand (Hong Kong/Japan) | Strength, kingly aura, control | Suitable for heavy-duty tasks such as industrial grinding and paint removal. |

| Tiger | Tiger (some Asian brands) | Fierce, explosive, and fast | High efficiency and strong grinding force, suitable for rapid metal grinding. |

VII. Conclusion: Color is a clue, not a standard.

The color of sandpaper is a visual representation of its sanding performance and product range. What truly determines the sanding effect are the grit size, abrasive type, application method, and target material. Color provides clues to help you quickly assess and match sandpaper, but...It cannot replace professional judgment。

PS:As an Amazon Affiliate member, I earn commissions from qualified purchases.